AQC HR

HIGH RESOLUTION AUTOMATIC QUALITY CONTROL

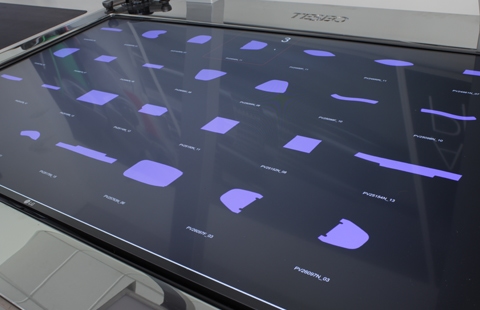

Inspection station with 4K 55” (124 cm) screen, with 12 high definition cameras for dimensional and quality control of perforation.

ENGINEERED FOR AUTOMOTIVE

ENGINEERED FOR FOOTWEAR

ENGINEERED FOR LEATHER GOODS

AQC

HIGH PRECISION VISUAL SYSTEM FOR AUTOMATIC QUALITY CONTROL

Control station equipped with 4K 55” (124 cm) screen, with fixed plane, which satisfies all the dimensional control needs of cut parts.

HD CAMERAS

ENGINEERED FOR AUTOMOTIVE

ENGINEERED FOR FOOTWEAR

ENGINEERED FOR LEATHER GOODS

AQC XL

HIGH PRECISION VISUAL SYSTEM FOR AUTOMATIC QUALITY CONTROL

Station for dimensional control of large panels with 4K 75” (170 cm) screen. Adjustable workstation in inclination and height, for maximum accessibility and ergonomics.

HD CAMERAS

ENGINEERED FOR AUTOMOTIVE

ENGINEERED FOR FOOTWEAR

ENGINEERED FOR LEATHER GOODS

AUTOMATIC QUALITY CONTROL THANKS TO THE POWERFUL VISUAL SYSTEM WITH 3 HIGH DEFINITION CAMERAS

Immediate compliance report

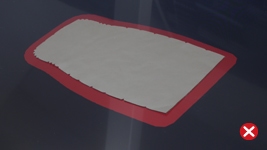

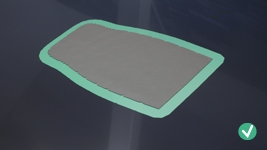

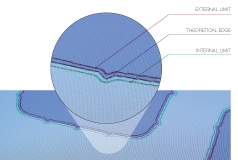

DIMENSIONAL CONTROL The dimensions are detected with a precision of 0.15 mm and the compliance with the set values is reported.

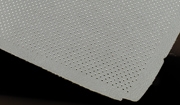

PERFORATION CONTROL The system detects imperfect or missing holes and their possible wrong position.

MATERIAL FLAWS CONTROL The system recognizes defects or residual marks on the surface that are present in areas of the pattern where they are not allowed.

INTERACTIVE CONTROL

Designed to achieve greater accuracy and for irregular shapes, the dimensional interactive control allows to place manually the part on the exact pattern which show pre-defined inside and outside allowance.

INTERACTIVE RE-LOADING ASSISTED BY A VISUAL SYSTEM

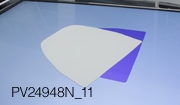

The parts, which are non-compliant after the traditional manual quality control, can be easily re-loaded in the cutting job on the MOB AQC. The non-compliant part is placed on the monitor.

The system automatically recognizes the right pattern (name, order and material) and re-loads it into the cutting job.

The operator can manually enter the number of pieces to re-cut. Alternatively an automatic recognition piece by piece can be carried out.

QUANTITY TO RE-CUT

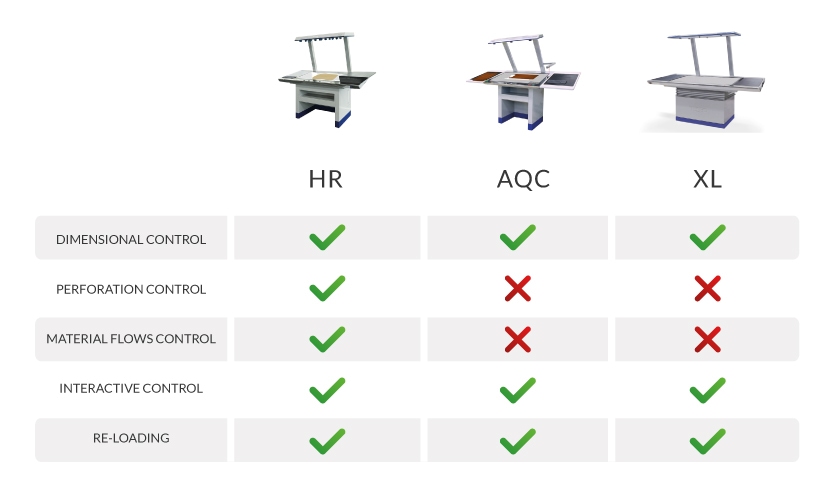

COMPARATIVE TABLE OF THE 3 MODELS