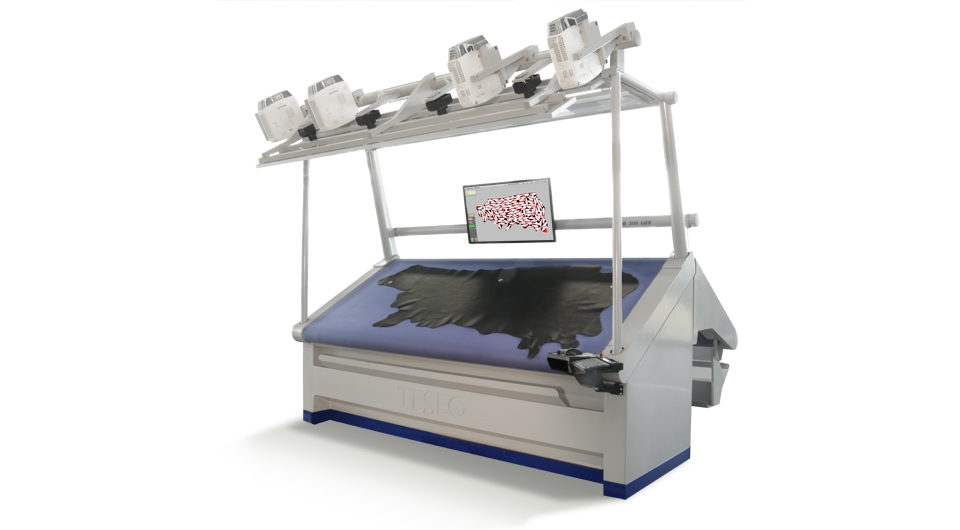

MOB 300 LUX+

Leather inspection and classification table, provided with Meti software, useful for manual or automatic scanning and nesting. 3000×1200 surface, sectorized and sucked, with conveyor and double inspection sides.

PROJECTORS

HD CAMERAS

ENGINEERED FOR AUTOMOTIVE

ENGINEERED FOR FOOTWEAR

ENGINEERED FOR LEATHER GOODS

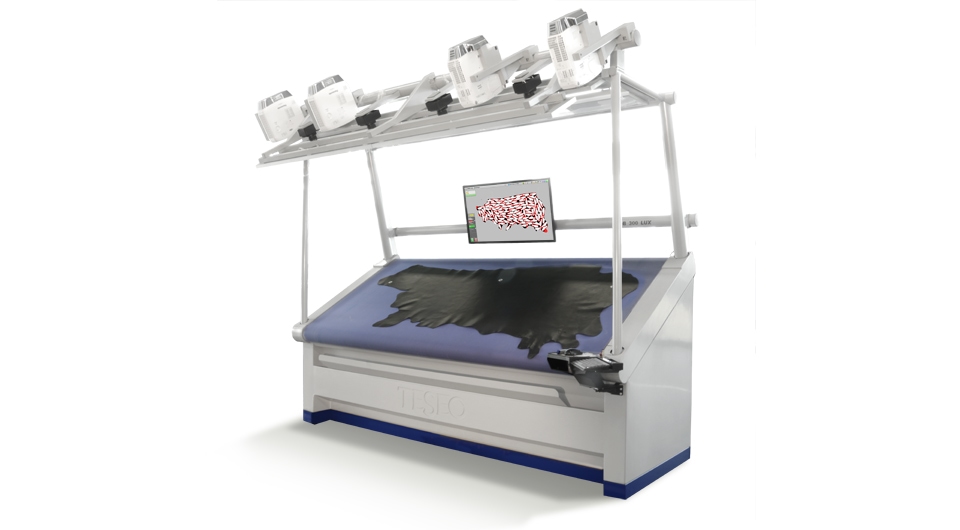

MOB 300 LUX

Leather inspection and classification table, provided with Meti software, useful for manual or automatic scanning and nesting. 3000×1200 surface, sectorized and sucked, with a conveyor.

PROJECTORS

HD CAMERAS

ENGINEERED FOR AUTOMOTIVE

ENGINEERED FOR FOOTWEAR

ENGINEERED FOR LEATHER GOODS

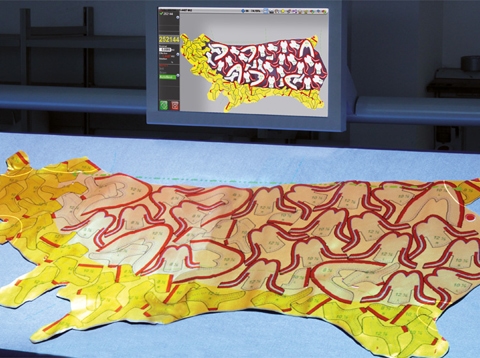

THE MOST EFFICIENT NESTING IN THE MARKET

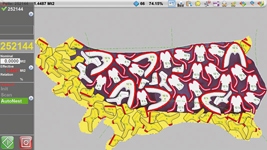

METI is the most powerful software for automatic placement with management quality areas for leathers.

The software is extremely powerful: it performs automatic nestings and assisted placements with customized strategies. To obtain the maximum of productivity and quality, it automatically optimizes the cutting path, it reduces common lines and minimizes movements and ways, removing the “overcutting” and reorganizing the pieces and the lines’ sequence.

The software is really simple and it requires just a couple of hours of instructions to be operative.

On the top you can see an example of placement for furniture and on the bottom there is a placement for leather goods.

The automatic placement is customized according to the product and it takes approximately 30 seconds to be performed.

SCANNING AND QUALITY CONTROL AND MARKING OF DEFECTS

The scan takes only 3 seconds, covers the entire working area and it is static to ensure a perfect quality of the picture, making visible even the smallest detail of the leather texture (resolution 0.25 mm).

The mark of the quality areas, the direction lines of the leather and every reference traces are shown instantly on the leather placed on the floor, where it will be directly cut. This ensures the highest accuracy of nesting and the absolute control in each following stage.

PRE-MARKING

Pre-marking is done with different colors that METI software automatically distinguishes for quality area and type of leather defects. The special inks have been designed to leave no permanent traces on good quality areas.

WILD

WIRELESS LEATHER DIGITIZER

The exclusive WiLD system allows to virtually mark the defects and the different quality areas, without leaving any trace on the leather.